How to Use:

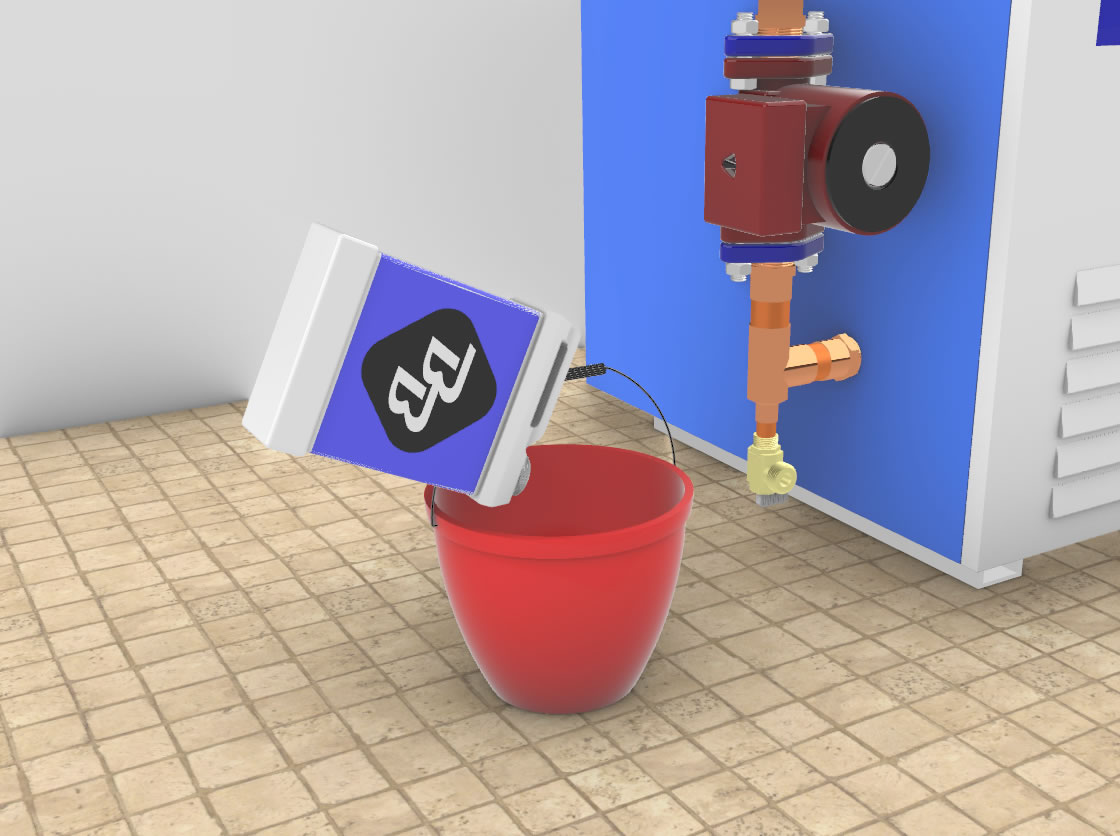

Pour Your Treatment Chemical Into A Bucket

Fill a small bucket with the boiler treatment chemical you are going to inject into the boiler.

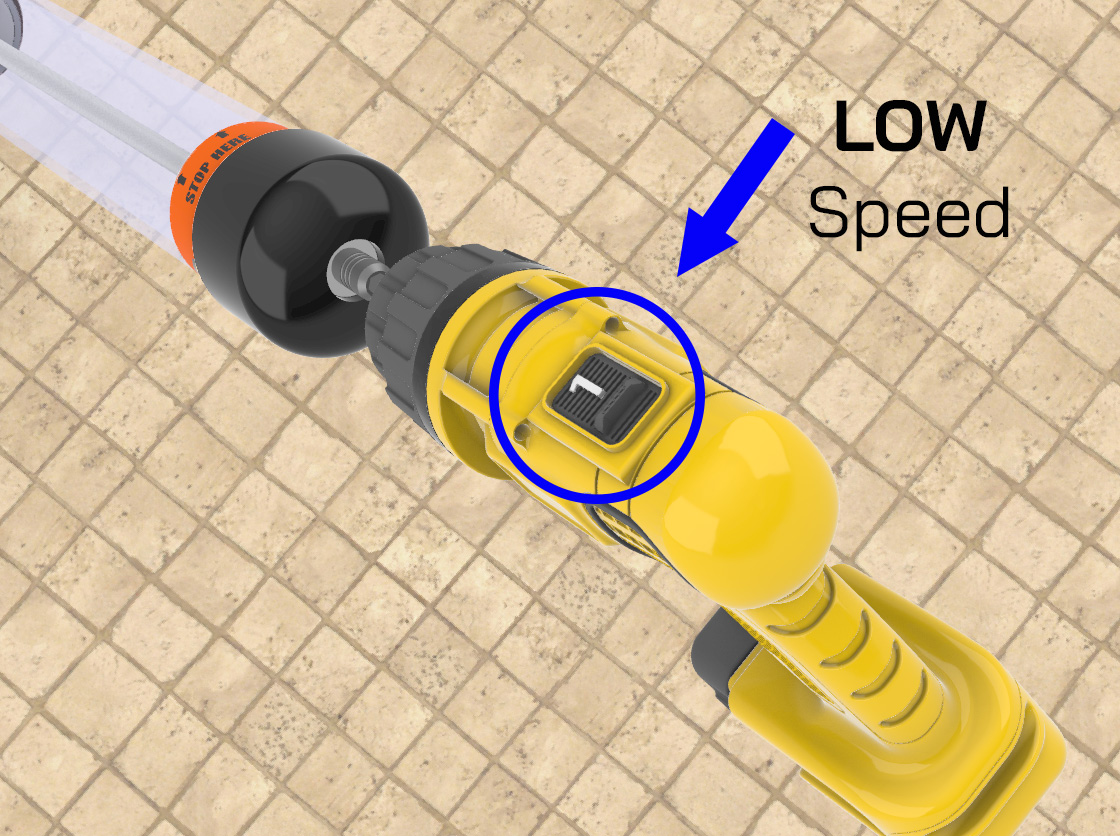

Set Your Drill To LOW Speed

It is important set your drill to LOW speed when operating the Boiler Booster. Moving the plunger up and down the Boiler Booster drive rod too quickly will cause premature wear.

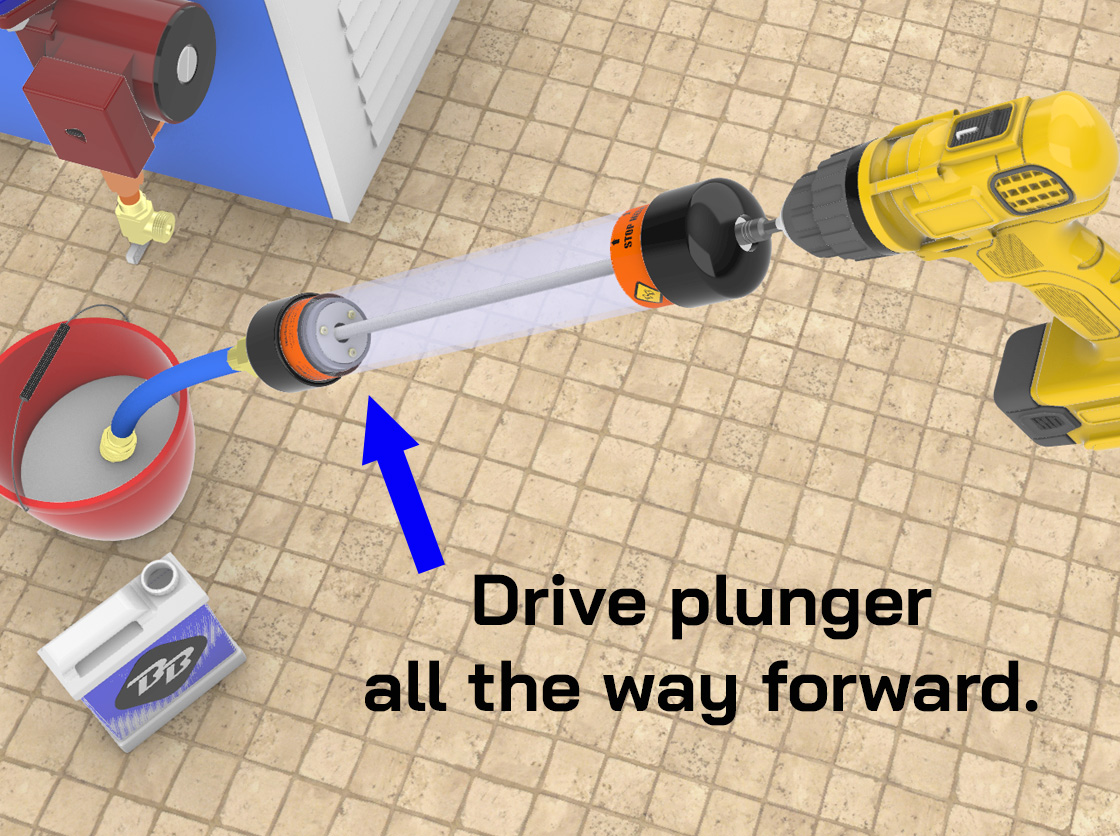

Prepare To Siphon Boiler Treatment Into The Boiler Booster

Make sure the Boiler Booster plunger is all the way forward in the Boiler Booster. If it isn’t, set your drill to FORWARD and gently move the plunger all the way forward until you hear a clicking sound. This sound will let you know the plunger can go no further and is ready to siphon. Use the included 5/16″ hex socket bit to connect the Boiler Booster to your cordless drill.

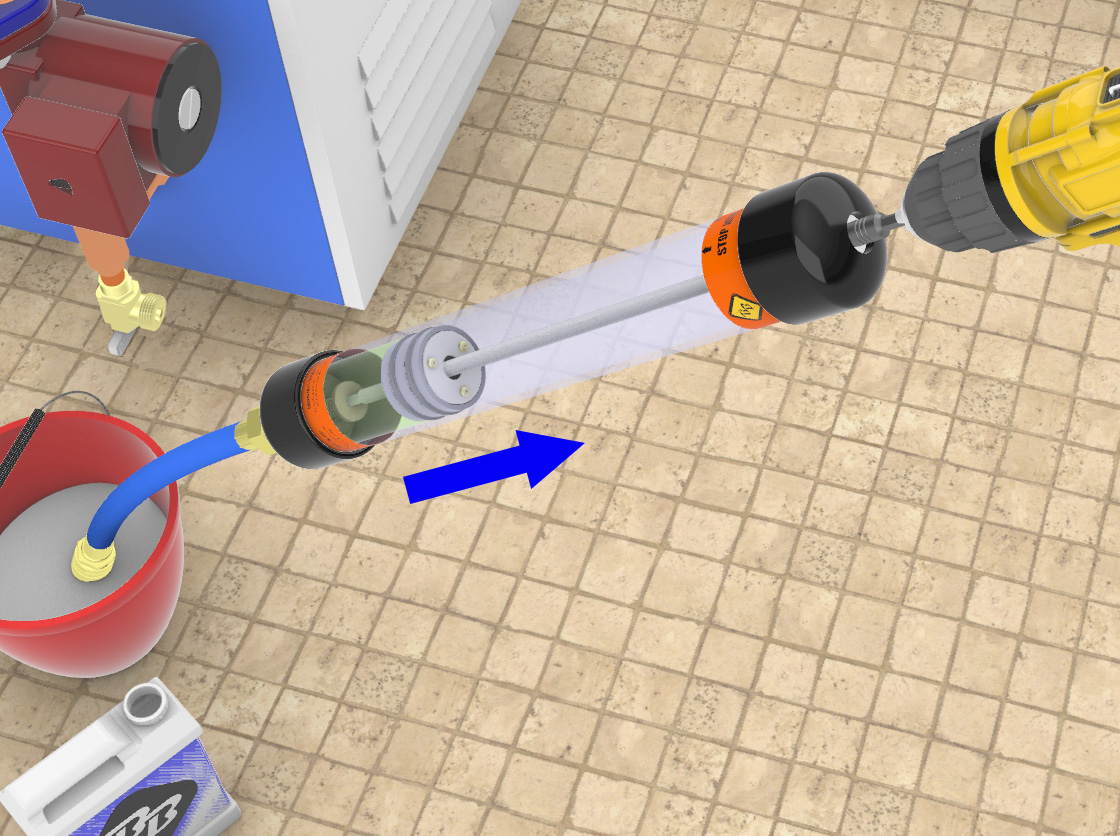

Pull Boiler Treatment Into The Boiler Booster

With your drill set to LOW speed and set to REVERSE, place the Boiler Booster’s hose into the bottom of your bucket of boiler treatment chemical. Run your drill in reverse to fill the Boiler Booster with your boiler treatment chemical. On low speed, this should take about 30 seconds.

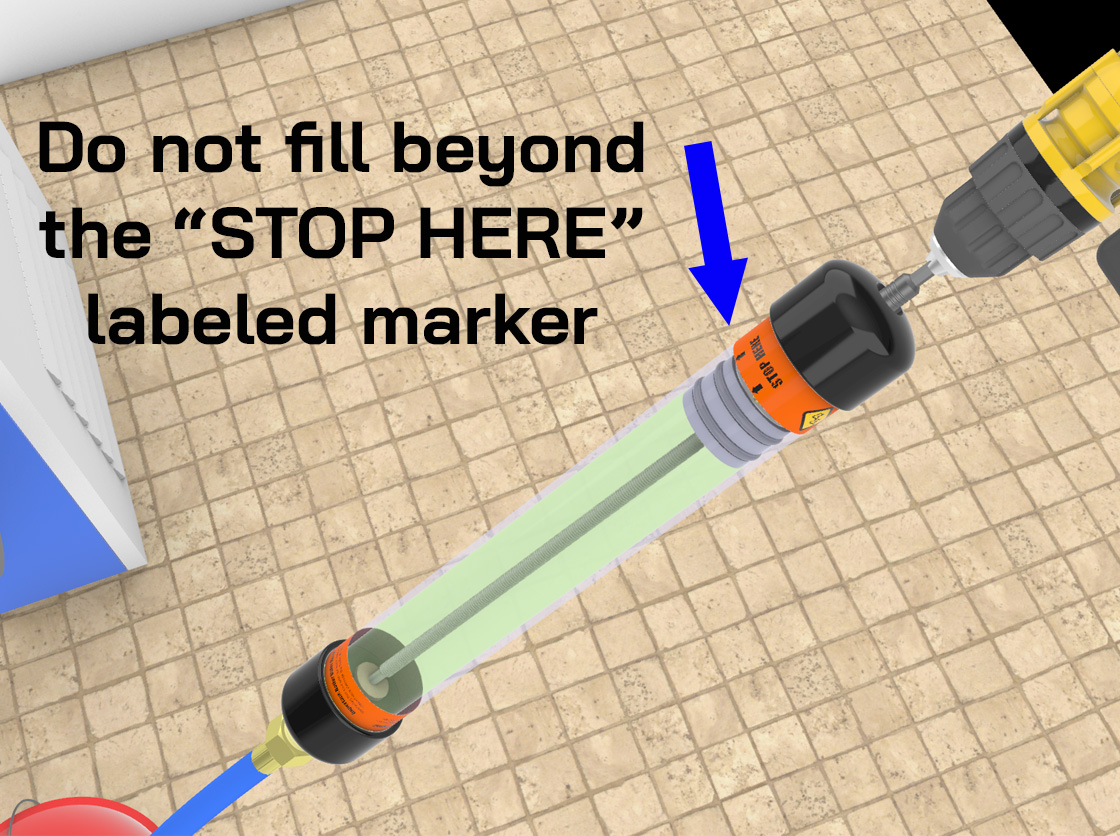

Stop Filling The Boiler Booster Before It Reaches the “STOP HERE” marker

The “STOP HERE” at the rear of the Boiler Booster is a label to let you know when the Boiler Booster has reached its maximum capacity. When the plunger reaches this label, stop the drill – DO NOT GO PAST THE MARKER. Going past this point can cause the plunger to suddenly stop, making the Boiler Booster difficult to hold.

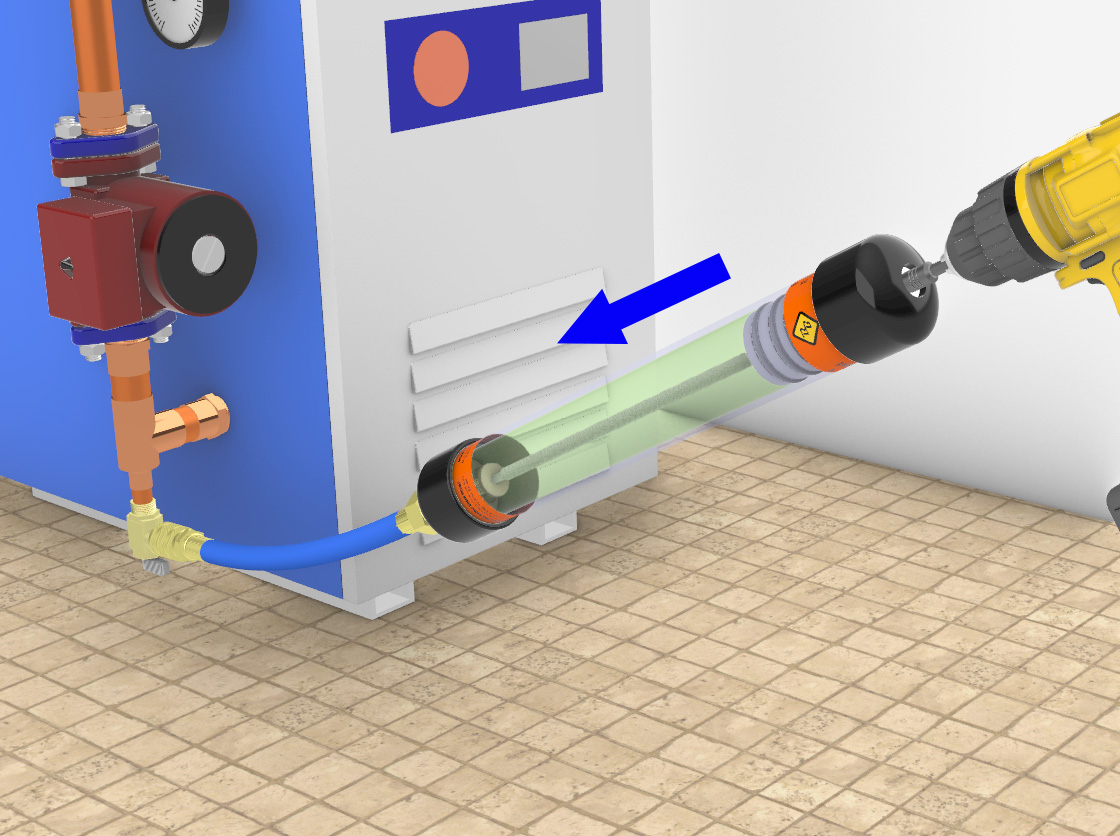

Connect The Boiler Booster

Using the included female brass hose swivel connector, connect the Boiler Booster hose to an available hose bib on the hydronic boiler system. Once firmly connected, turn the hose bib on. This will equalize the pressure between the boiler and the Boiler Booster.

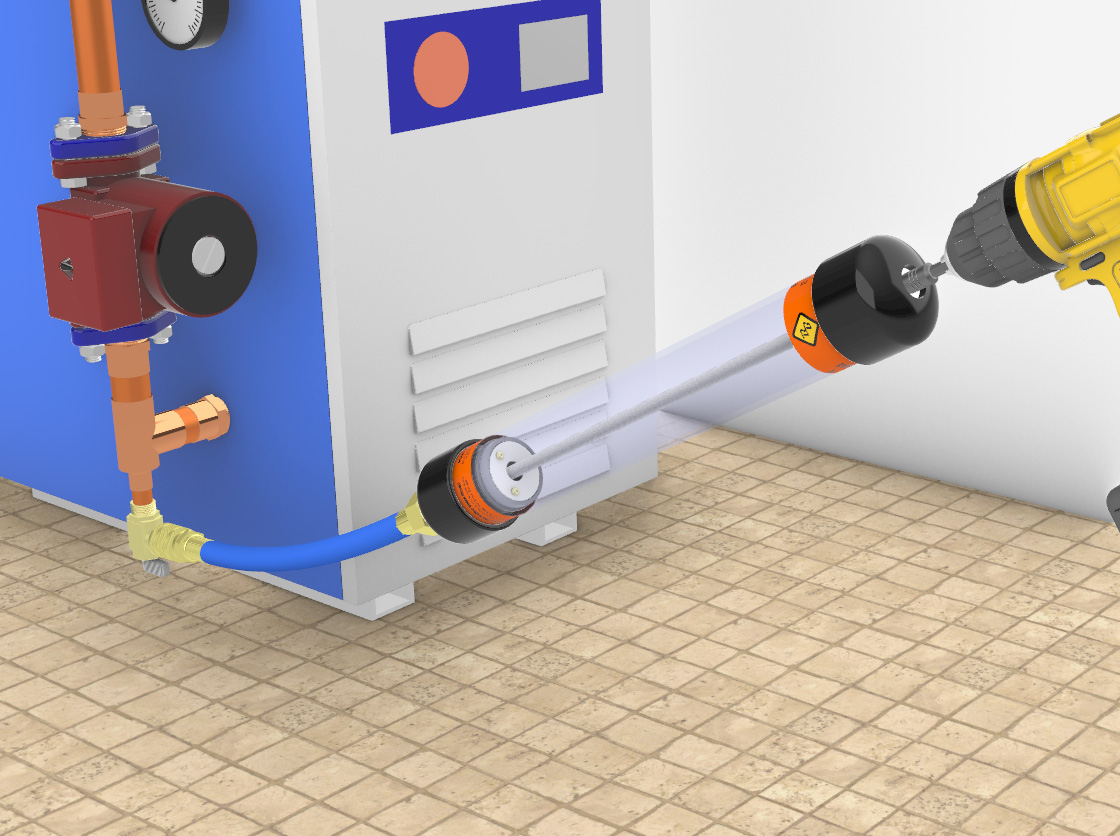

Inject The Boiler Treatment Into The Boiler

Put the drill on LOW speed and set it to FORWARD. Run your drill until the plunger injects all of your boiler treatment chemical into the boiler. On low speed, this should take about 30 seconds. Keep an eye on the boiler pressure to ensure it is approximately 10-15psi below its 32psi limit. When injecting 32 ounces of boiler treatment into a 2000 square foot house with a typical 5 gallon expansion tank you can expect an increase of approximately 2-4psi of hydronic system pressure.

The Plunger Will Click When Finished

When the boiler treatment has been completely injected into the hydronic system, the plunger will stop moving forward and make a clicking sound. This indicates it has injected all of its contents into the boiler.

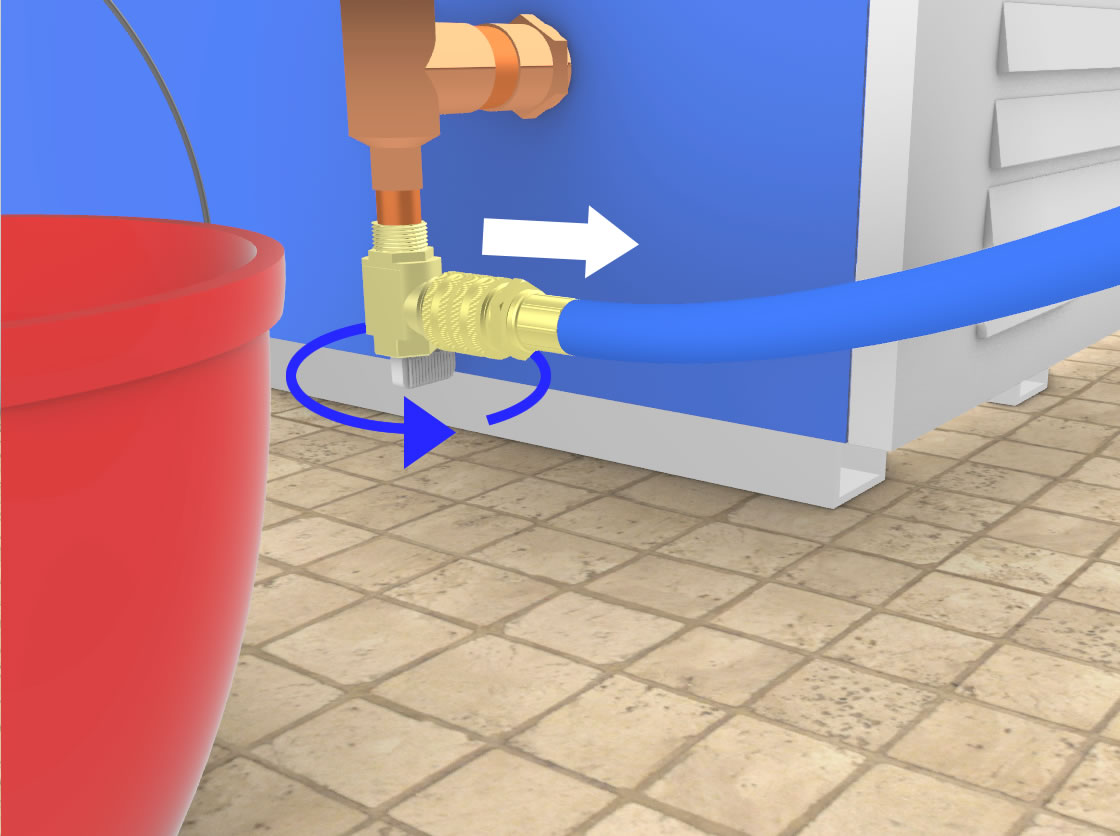

Disconnect The Boiler Booster

Turn off the hose bib. Relieve any residual pressure from the hose and Boiler Booster by putting the drill into reverse and move the plunger back about an inch. Disconnect the hose.

Job Completed